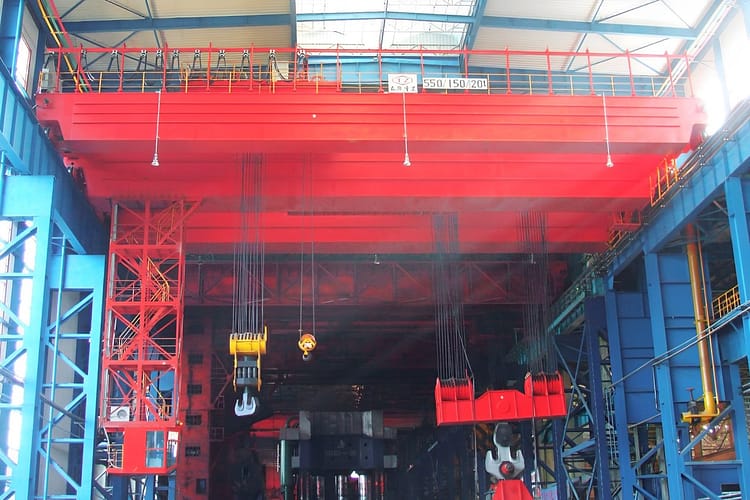

Forging Overhead Cranes

Forging overhead crane is a kind of lifting equipment specially used in the metallurgical industry. It is used for lifting, buffering, and overturning forgings (large solid hot-melt metal), and forging and forming molded parts.

- Lifting Weight: 180t~550t

- Span: 24m~33m

- Lifting Height: 17m~28m

- Working Grade: A6~A7

- High Load Capacity

- Reliable and Stable Structure

- High Safety Standards

- Low Maintenance Costs

Product Introduction

Forging overhead cranes, tailored for metal forging industries, use main and auxiliary hooks with a special spreader to manipulate forgings. They position forgings on a hydraulic press for shaping into qualified products. Equipped with buffer and brake release devices, these cranes handle the shock loads during forging, ensuring safe and efficient operations.

Product Structural Forms

Triple-Beam Four-Track Dual Trolley Model: This widely used model has its main and auxiliary lifting mechanisms installed on two separate trolleys, with the distance between the main and auxiliary hooks adjustable as needed. It is suitable for situations where the length direction of the forging aligns parallel to the plant's tracks.

Double-Beam Double-Track Single Trolley Model: This compact structure model features both the main and auxiliary lifting mechanisms installed on the same trolley. It is primarily used in forging scenarios where the axis direction of the forging is arranged perpendicularly to the plant's tracks.

Key advantages of forging overhead cranes

- High-Temperature Environment Adaptability: Forging cranes are often required to operate in high-temperature forging workshops. Their construction and material selection are designed to withstand high temperatures, ensuring stable operation and longevity.

- Strength and Stability: The forging process demands high strength and stability from the cranes to handle the impacts and vibrations encountered during forging.

- Positioning Accuracy: Precise positioning is crucial in the forging process. Forging cranes typically offer high positioning accuracy to ensure workpieces are accurately placed in the forge dies.

- High Load Capacity: Forging cranes are required to carry and manipulate heavy dies and workpieces, thus their structure and materials are designed to provide sufficient strength and load-bearing capacity.

- High Lifting Height: Forging cranes need to provide sufficient lifting height to accommodate different sizes of forge dies and workpieces.

- Protective Measures: Considering the heat, dust, and other harmful substances generated during forging, forging cranes often include protective measures like shields and cooling systems to ensure the safety of both equipment and operators.

Key Applications Scenarios

TZCO cranes excel in efficiency, adaptability, safety, versatility, durability and precise material handling, making them important lifting equipment for metallurgical casting operations.

Forging Industry

High-Temperature Environments

Workpiece Turning

Related Cases

Explore our case studies to discover how our innovative solutions have propelled our clients towards achieving their objectives.Get Started Now!

We Guarantee A Rapid Response To All Your Questions And Inquiries, Ensuring You'll Hear Back From Us Within 24 Hours.

- Email: tzcranes@gmail.com

- Address: No. 99, Yuantai Road, Equipment Manufacturing Park, Economic and Technological Development Zone, Datong City, Shanxi Province, China.